Most common problems of solar PV plants equipment are related to PV modules and inverters.

PV modules defects can add up to module under performance of 20%! It is therefore crucial to detect as soon as possible these problems:

Microcracks

Low cost solar cells can have structural defects which are not visually detectable, these defects are known as microcracks. Due to the self- performance effect of the PV module, thermal cycles happen in the module during transitions between day/night and different seasons of the year. These defect can generate damages in the cell contact points to evacuate the current. In this scenario, a solar cell could be severely damaged. Even though cells have serial connection inside the PV modules, this will limit the current of the whole panel and consequently reduce the whole module performance proportionally to the number of cracked cells.

PID effect

PID stands for “Potential Induced Degradation”. This phenomenon occurs when there is a relative voltage with regard to PV panel ground connection. Although, for safety reasons, PV panel frame is normally connected to ground, a relative voltage between ground voltage, and voltage generated by a solar panel could exist. In some cases this generates a voltage field which partially discharges the current generated by the panel. The consequence of this effect, is the continuous performance degradation and the accelerated aging of the PV panel.

Improper installation

One of the most simple and common defect at the same time, is the improper installation of PV modules. It must be verified against the design that the right clamps are used, expansion joints respected and mounting structures appropriated and correctly oriented. Otherwise modules can break or even fly away in some cases.

Hot spots

Hot spots in PV panels are mainly caused by bad soldered connection points or structural defects in the solar cells. These wrong connections cause regions of the panel with very low resistivity and finally gets part of the current that must be generated by the cell in normal conditions. These currents can be elevated and produce hot spots in the welded point and/or inside a cell. This phenomenon can generate short circuits, and in both cases, it reduces the performance and the lifecycle of the PV panel.

Snail tracks

When solar cell has been manufactured with low cost silver paste (used in the front metallization contacts of the solar cells), it is probable that humidity zones appear in the rear part of the module which finally is transmitted to the front part of the module. There is a chemical reaction between silver paste and EVA (“ethyl-vinyl-acetate”) module encapsulant, which liberates silver oxide and hydrogen. This effect is transmitted from the rear part of the panel and produces a chemical degradation in the front part of the solar cell which can affect its performance. Snail track defect position is normally correlated with microcraked cells.

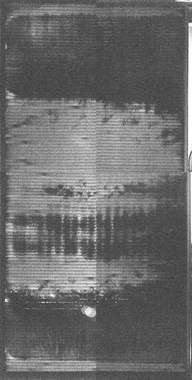

The corrosion of the transparent conductive layer of the panel occurs when moisture penetrates around module edges. This specially can happens in thin film PV panels which are frameless, manufactured based on glass substrates. Since the moisture penetrates into the modules, dark areas appear, starting in the outer zone of the module and depending of the severity, extends to the rest of the surface. When this happens, the under performance of the module is normally linear dependent with the corroded areas (dark areas) present in the panel.

According to the defect type, Greensolver can define and manage the specific tests required to detect them and then fix the issues, in order to reduce any underperformance. Don’t hesitate to contact us for more information!