Co-Authors: David Roissé & Ypatios Moysiadis

Date: 18/01/2019

Operation & Maintenance (O&M) is an integral of the critical services provided in any generating asset. Despite the significant drop in operational expenditure, the prices have been

Greensolver took part in the initiative led by Solar Power Europe for the development of standard guidelines across all service providers in Europe. This year the engagement and the participation for the launch of O&M Best Practices Guidelines v3.0 was even higher. This document is the definite guide for every service provider within the solar PV industry. It provides a clear outline of all critical elements that both asset owners and service providers should consider on every Service Level Agreements (SLA) and also clearly outlines the best practices currently adopted by the industry in relations to O&M. You can download the Guide here.

One of the most critical points of the Guide is the contractual framework which translates in the final SLA.

Typically the minimum services described in an O&M contract should include:

– Power plant operation:

- Plant documentation management

- Plant supervision

- Plant operation

- Management of change

- Reporting to technical asset manager

– Power plant Maintenance:

- Preventive maintenance

- Corrective maintenance

- Rules for extraordinary maintenance

- Additional maintenance services (module cleaning, vegetation management, maintenance of security equipment, …)

– Spare pare management

Within this minimum contractual scope, four points should be given extra attention. The contractual guarantees, regarding:

- Availability

- Response / Resolution time guarantee instead of Performance ratio guarantee

– Incentivised Operation / Bonus schemes and Underperformance Penalties / liquidated damages

– O&M contractors’ qualification, track record and quality certifications

– Spare parts management

Concerning the contractual guarantees, the main guarantee is the availability (recommended on Energy based rather than Time based). As a best practice the minimum Guaranteed availability is of 98% over each operational year. However, depending on the country it is very often the availability guarantee to be at a minimum of 99

A recent development to O&M contracts is that asset owners have started moving away from Performance Ratio (PR) Guarantees towards Response Time (RT) guarantees. Response Time (RT) means the time that the O&M takes to respond to an alarm, investigate the fault plus the intervention time to repair the fault

Key changes in the contractual obligations, for example, the introduction of new KPIs like the RT guarantees can help safeguard solar assets from underperforming service providers.

Performance Ratio monitoring and measurement depends heavily on the interpretation of installed sensors on site (pyranometers) which in turn require constant calibration and efficient management.

By adopting Response Time as a key metric, both contractual parties have a more transparent way of operating based on a pre-agreed set of parameters in direct relationship to the severity of the fault and the percentage of generation loss on site.

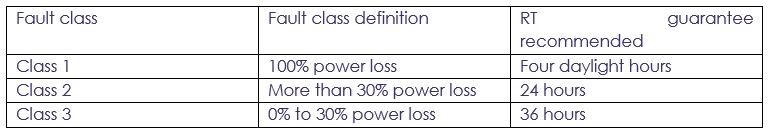

For example, according to the Fault class (1 to 3), the RT could be:

A further improvement on O&M contracts is the inclusion of Resolution Time (ReT) guarantee for specific types of faults (inverter swap, fuse change, etc.). Resolution time (or repair time) is the time to resolve the fault starting from the moment that a qualified engineer reaches the solar PV plant. Resolution time can be measured more effectively when the O&M provider is fully responsible for the Spare Parts Management, or there is a pre-agreed stock level of key parts stored on dry storage on site or close by for quick access. Furthermore, ReT guarantee can be used as a metric to incentivise O&M Contractors when they over-perform on a specific fault/call-out.

Another critical point to check is the O&M contractor’s qualification. The O&M provider must have the means, skills and capabilities to operate and maintain the plant in accordance with their contractual obligations. It is wise to check the service provider’s track record and speak with referrals that the contractors will provide. Also, a good indicator always is the quality certifications that a contractor carries and their internal management systems (including H&S and training).

Experience and availability of a professional organisation, skilled teams and access to spare parts are essential for successful providers. As O&M services are a combination of remote operations services and local maintenance activities, it is necessary for the asset owner to make sure that both elements are well managed and interfaces between operations services and maintenance services are well defined, especially when subcontracted to different entities by the O&M Contractor.

Greensolver can help you to compile and review the contracts and the SLAs with all your O&M providers. We can help you to improve your O&M services and thus the LCOE and ROI of your asset.

Do not hesitate to contact us for more information.